What environment is suitable for mining elevators and how to improve the safety of mining elevators

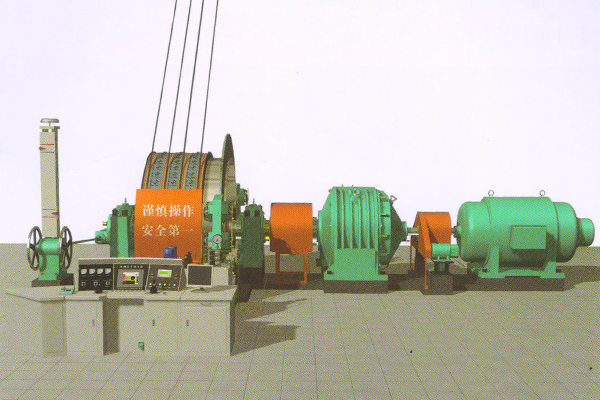

Mining elevators are mainly used for transporting materials and personnel in inclined tunnels and small vertical shafts on the surface or underground of metal mines, iron mines, gold mines, non-metallic mines, coal mines, gangue, and other mines. They are commonly used for lifting materials in the main shaft, carrying people and materials, lifting auxiliary shafts, inclined shafts, vertical shaft transportation, etc., and play an important role in the entire mine. At the same time, mining elevators need to be selected according to the conditions of the mine wellhead, and non-standard models need to be negotiated with the customer before implementation.

Please note that the use of mining elevators must strictly follow relevant regulations and operating requirements to ensure safety.

The following measures can be taken to improve the safety of mining elevators:

1. Strictly implement safety technical measures: Before using the hoist, conduct strict safety technical inspections and tests to ensure that all components of the hoist are intact and undamaged, especially key components such as the braking system and safety protection devices.

2. Strengthen safety management: Establish and improve the safety management system and operating procedures for elevators, enhance employee safety education and training, and enhance employee safety awareness and operational skills.

3. Reasonable use and maintenance: According to the usage requirements of the hoist, arrange the usage time and frequency reasonably to avoid overloading and excessive use. At the same time, regular maintenance and upkeep should be carried out on the hoist to ensure the normal operation of the equipment.

4. Install safety protection devices: Install safety protection devices around the hoist, such as guardrails, protective nets, etc., to prevent personnel from approaching dangerous areas.

5. Regular inspection and testing: Conduct regular inspections and testing on the hoist, and promptly address any hidden dangers. At the same time, regular calibration and adjustment of equipment performance and safety protection devices should be carried out to ensure their effectiveness.

6. Use a reliable electrical system: The electrical system of the hoist should use a reliable power supply and control system to avoid accidents caused by electrical faults.

7. Equipped with qualified drivers and signal workers: The operation of the hoist is carried out by qualified drivers and signal workers. The drivers have undergone professional training and assessment, and the signal workers also have corresponding operating skills and safety awareness.

8. Strengthen equipment supervision: For important equipment such as elevators, equipment supervision and management should be strengthened, equipment archives and maintenance records should be established, and real-time monitoring and management of equipment maintenance and usage should be carried out.

9. Establish emergency plans: For possible emergencies, establish corresponding emergency plans and conduct regular drills to ensure that measures can be taken quickly in emergency situations and reduce accident losses.

In summary, improving the safety of mining elevators requires starting from multiple aspects, including strengthening equipment safety technical inspections, establishing sound safety management systems and operating procedures, reasonable use and maintenance of equipment, installing safety protection devices, and regularly inspecting and testing equipment performance. At the same time, it is also necessary to equip qualified drivers and signal workers, strengthen equipment supervision and management, and establish emergency plans to respond to possible emergencies.

News and information

Latest news- 282024.03

Iranian clients come to the company to negotiate cooperation

- 022023.11

What environment is suitable for mining elevators and how to improve the safety of mining elevators

- 022023.11

What are the advantages of a drilling wheel and where can it be used

- 022023.11

How to deal with common faults of mining elevators?

- 022023.11

What are the differences between scheduling winches and mining hoisting winches

- 022023.11

Why is a belt conveyor suitable for transporting coal